Current sensors are designed to convert AC and / or DC current flowing through the conductor into the standardized voltage or current. They usually have a linear dependence of the output current or voltage on the measured current, which allows them to be used for subsequent registration with a self-recording voltmeter. Current measurement methods can be both contact and non-contact. There are several ways to measure the flowing current in a conductor. The measured current can be constant or variable depending on which the measurement method is chosen.

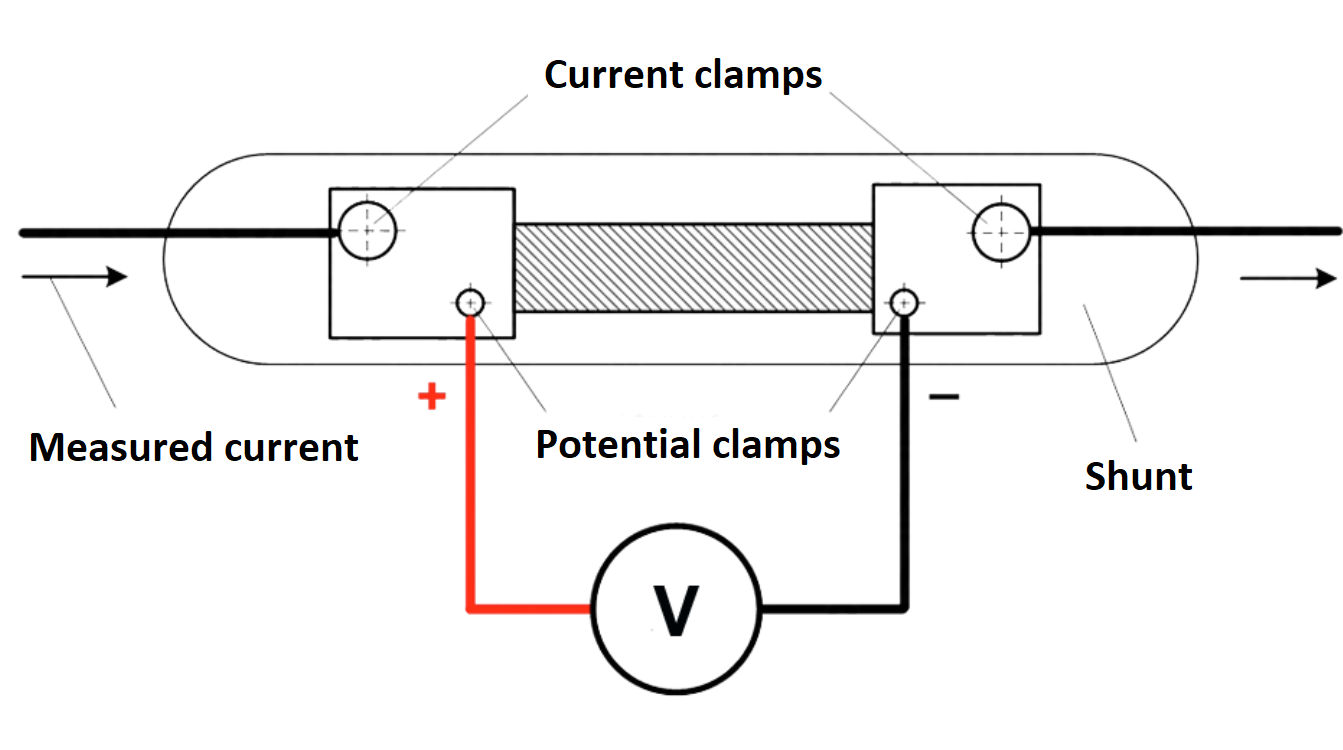

The most common universal and inexpensive contact method is measurement of the voltage drop that occurs when current flows through the shunt, a pre-known resistance, designed for the maximum possible current in the circuit. Shunts have a standardized voltage drop value of 75 mV (there are Western analogues with a value of 60 mV), reduced to the maximum permissible current, which ensures permissible heating of the shunt by flowing current within the specified error limits indicated on the shunt.

Both alternating and direct current can be measured with the help of a shunt, the measurement scheme is very simple:

However, you should bear in mind that this contact method is not isolated, i.e. the measuring circuit is galvanically connected to conductor, so it is possible to directly remove the voltage from the shunt if the potential differences in the galvanically connected circuits are within the permissible values for the input range of the self-recording voltmeter. With the help of shunts without additional equipment, it is possible to measure the currents of batteries or secondary circuits of power sources that have galvanic isolation from high voltage. If you need to use a shunt for measurements, then you need to take into account galvanic isolation of the measured circuit made by self-recording voltmeter. For this purpose an isolating amplifier УСО-AISO is used to provide both galvanic isolation of each channel from the measuring device as well as the opportunity to amplify the voltage removed from the shunt 100 times and bring it to a convenient 7.5 V voltmeter for maximum current at a single gain. 25% of the margin will provide registration of emissions and ripples if necessary.

Shunt current measurement is still the most accurate and reliable method, since it introduces the least number of elements in the measured circuit that affects the accuracy of measurements, which provides the widest bandwidth and does not require power sources for this operation.

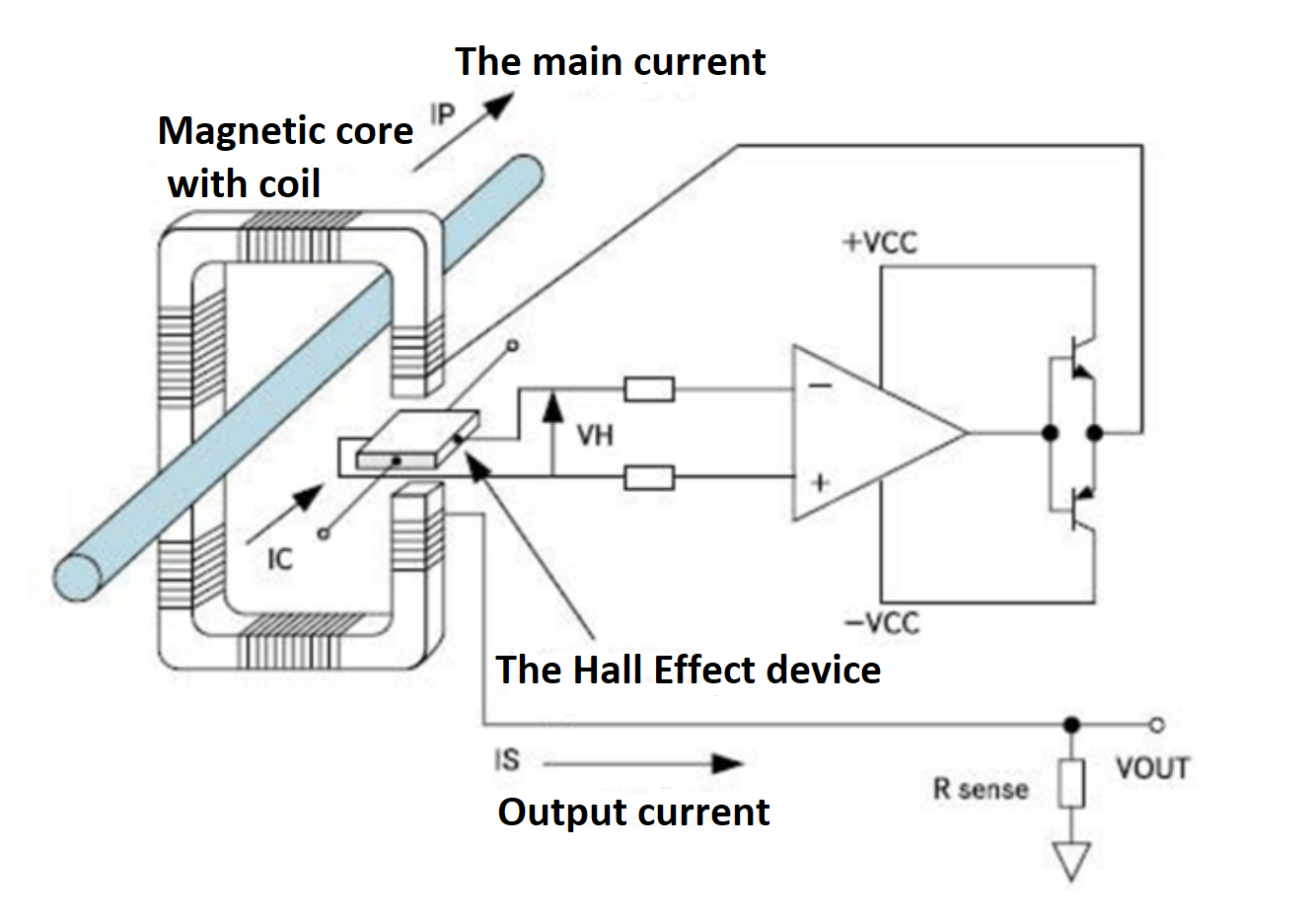

Another common non-contact method is the conversion of current flowing in a conductor using a Hall sensor, named after the discoverer of the effect of the occurrence of a transverse electric field in a semiconductor or a conductor placed in a magnetic field, Edwin Herbert Hall back in the 79th year of the last century.

This method has been currently widely used due to the significant spread and cheapening of semiconductor components, as well as the galvanic isolation inherent in this measurement method. Sensors based on this measurement principle can be viewed here: Hall sensors

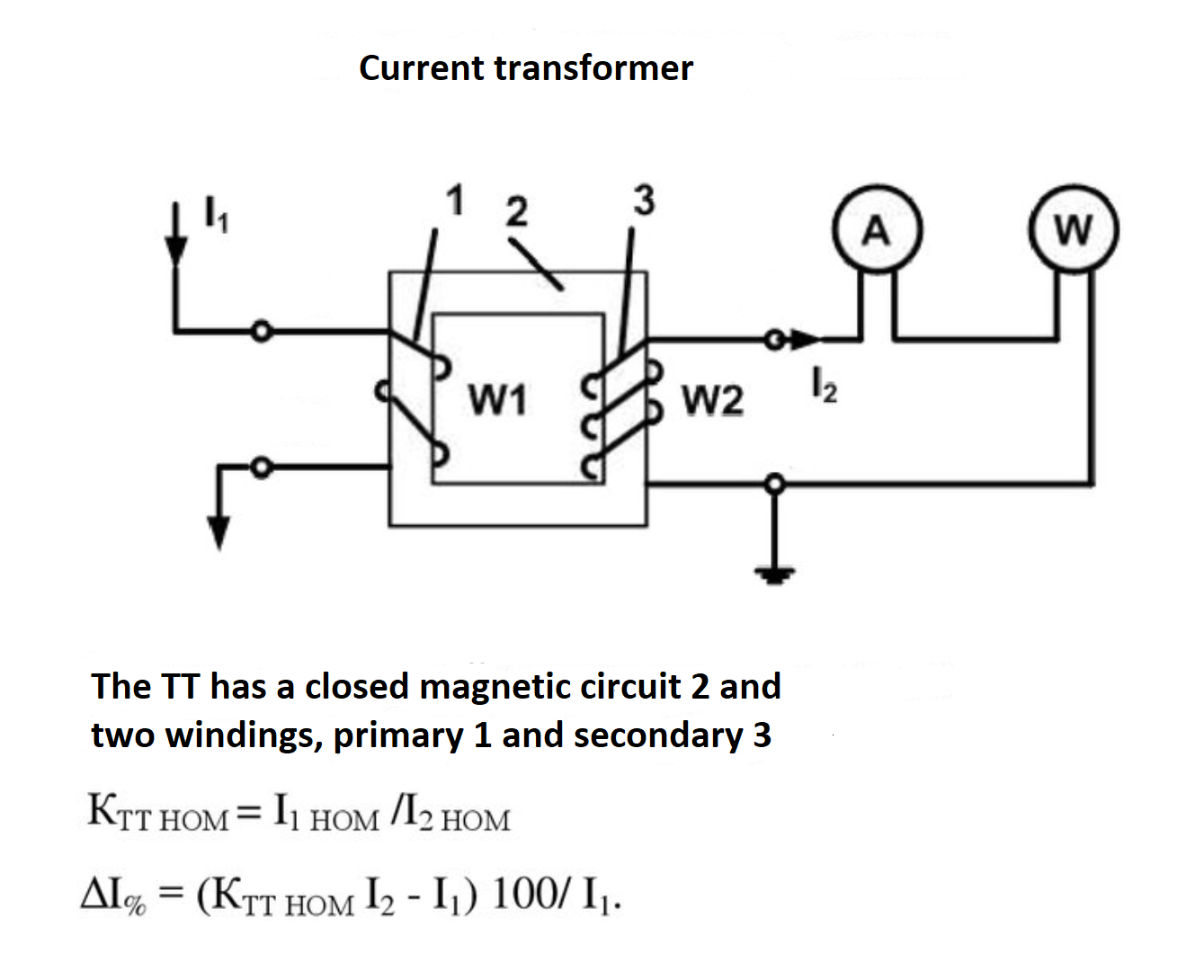

Other methods are designed to measure alternating current. So, one, not less common method of contact measurement of alternating current is a current transformer, through the primary winding of which the measured current flows, and the voltage proportional to the flowing current is removed from the secondary winding.

Not less widely used are current clamps, which belong to the contact free method and can have both a built-in Hall sensor and work according to the induction principle, when only alternating current is measured, and the clamps are essentially the secondary winding of the transformer on the opening external magnetic circuit that wraps around the conductor with measured current. The current flowing in the conductor induces a proportional voltage, which can be measured by repeating the above method of a current transformer.